Industry 4.0 & Industrial Metaverse

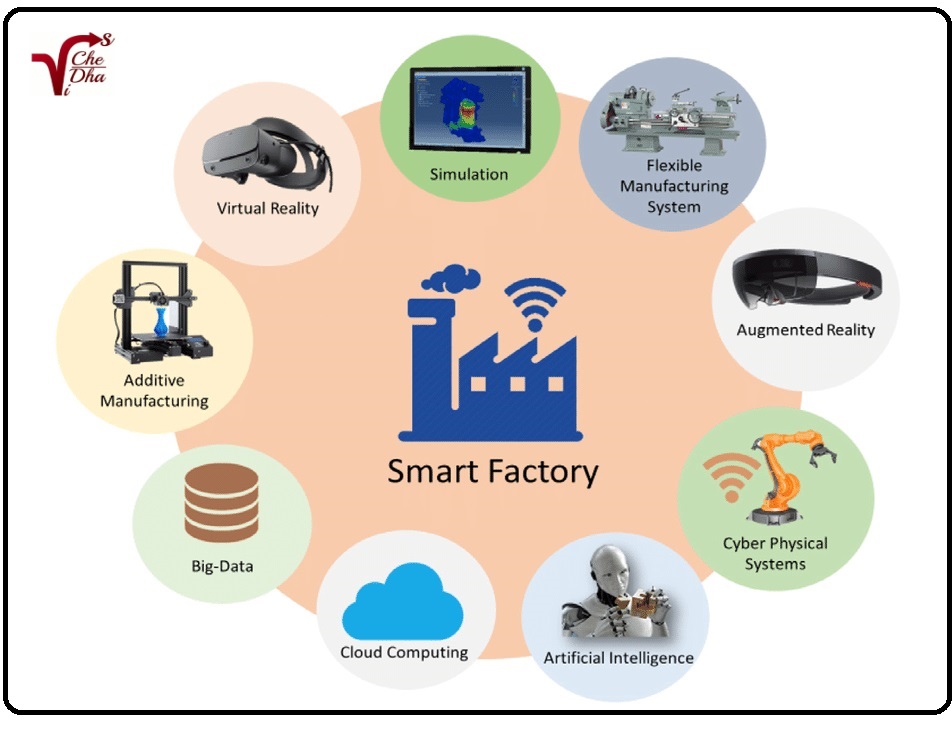

Industry 4.0 also known as the Fourth Industrial Revolution (4IR), represents the latest paradigm shift in manufacturing and industry. It encompasses the integration of digital technologies, intelligent automation, and data-driven processes to create a highly interconnected and smart industrial ecosystem.

Vischedha.ai heralds a new era of industrial transformation, where digital technologies redefine how we manufacture, operate, and innovate. It represents a shift towards intelligent, connected, and data-driven industrial ecosystems, shaping the future of global industries.

vischedha.ai Smart Factories Solutions

Data-Driven Decision Making:

Vischedha.ai empowers smart factories by championing data-driven decision-making through seamless integration. By harnessing advanced analytics and processing capabilities, Vischedha ensures that smart factories can effectively collect, analyze, and leverage data for informed decision-making. The integration enables real-time monitoring of production processes, predictive maintenance, and adaptive manufacturing strategies. Through this approach, Vischedha.ai enhances operational efficiency, optimizes resource allocation, and enables smart factories to respond dynamically to changing demands. The result is a more agile and adaptive manufacturing environment, where decisions are grounded in data insights for continuous improvement and innovation.

Automation and Smart Manufacturing:

Vischedha.ai leads the charge in automation and smart manufacturing, seamlessly integrating cutting-edge technologies for transformative solutions. Through intelligent automation, Vischedha enhances operational efficiency by deploying robotic systems and AI-driven processes. This integration ensures streamlined workflows, reduced downtime, and improved precision in manufacturing tasks. Smart manufacturing, powered by Vischedha.ai, involves real-time data analytics, predictive maintenance, and adaptive production strategies

Cloud Computing & Big Data Integration:

Vischedha.ai seamlessly integrates cloud computing and big data to provide a robust and efficient solution. Leveraging advanced technologies, Our solutions ensures a seamless collaboration between cloud-based computing resources and the processing of large datasets. This integration enhances scalability, allowing for the efficient storage, retrieval, and analysis of extensive data sets in real-time. The synergy of cloud computing and big data integration by Vischedha optimizes computational capabilities, enabling businesses to derive meaningful insights, make data-driven decisions, and achieve heightened efficiency in various applications and industries.

Augmented Reality & Digital Twins:

Vischedha.ai digital twin solutions is a virtual representation of a physical object, system, or process that mirrors its real-world counterpart. This dynamic simulation combines real-time data and IoT connectivity to create a comprehensive and responsive digital replica. Digital twins play a pivotal role in various industries, offering insights, monitoring capabilities, and predictive analysis. From optimizing manufacturing processes to enhancing maintenance strategies, digital twins empower organizations to make informed decisions, improve efficiency, and drive innovation.

Augmented Reality Projecting computer-generated images onto the real world, providing real-time guidance and information to workers.

Virtual Reality (VR) Creating immersive virtual environments, enabling remote training and collaboration.