Predictive Maintenance

Vischedha.ai Solutions Predictive maintenance (PdM) with AI, also known as predictive maintenance using machine learning (PdM-ML), is a revolutionary approach to asset management that utilizes AI algorithms to predict equipment failures before they occur. This proactive approach aims to minimize downtime, reduce maintenance costs, and enhance overall asset reliability. PdM-ML algorithms analyze vast amounts of data from various sources, such as sensors, operational logs, and maintenance history, to identify patterns and anomalies that indicate potential equipment failures. These algorithms can learn from historical data and predict the likelihood of future failures with high accuracy.

Key Benefits of PdM-ML

| PdM-ML Services | PdM-ML Description | Model Representation |

|---|---|---|

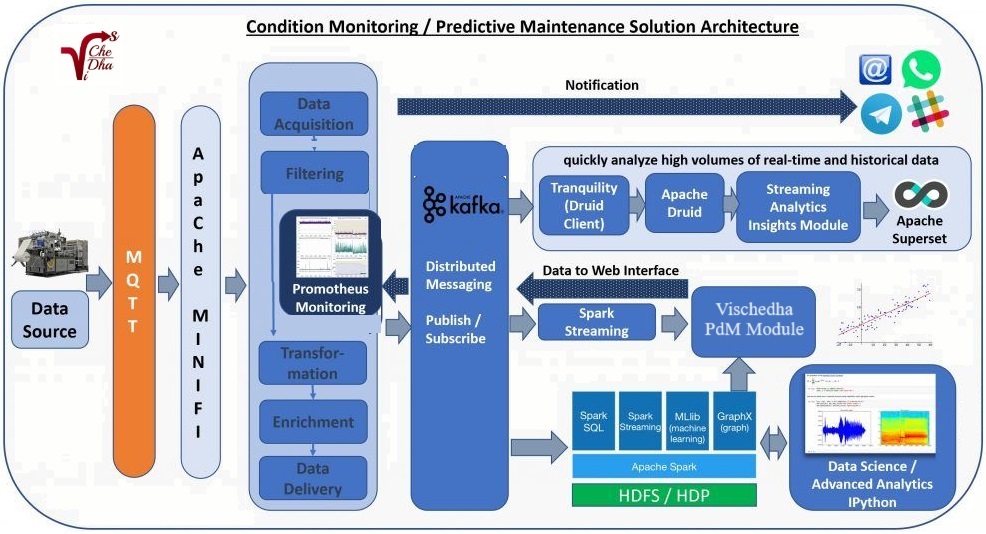

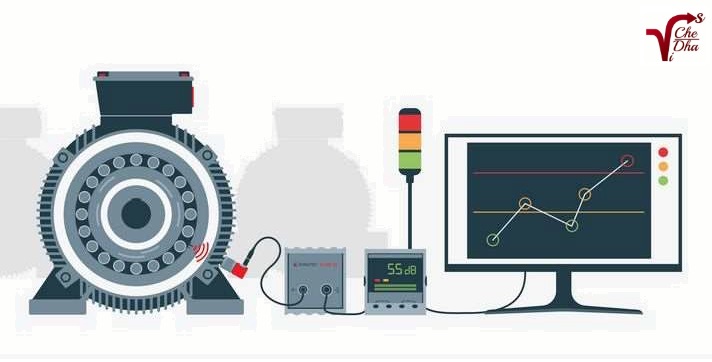

| Condition Monitoring | Leverage vischedha.ai PdM AI algorithms to consistently oversee and gather essential data from assets via an IoT framework, providing real-time updates on their status. |  |

| Reduced Downtime | PdM-ML enables businesses to schedule maintenance activities in advance, preventing unexpected equipment breakdowns that lead to downtime and production losses. |  |

| Enhanced Reliability | By proactively addressing potential failures, PdM-ML ensures that assets remain operational longer, minimizing the risk of breakdowns and ensuring continuous production.. |  |

| Optimized Maintenance Schedules | Vischedha's Predictive Maintenance AI empowers customers to craft highly effective preventive maintenance schedules. Our supported algorithms go a step further, suggesting optimized maintenance schedules that enhance operational efficiency |  |

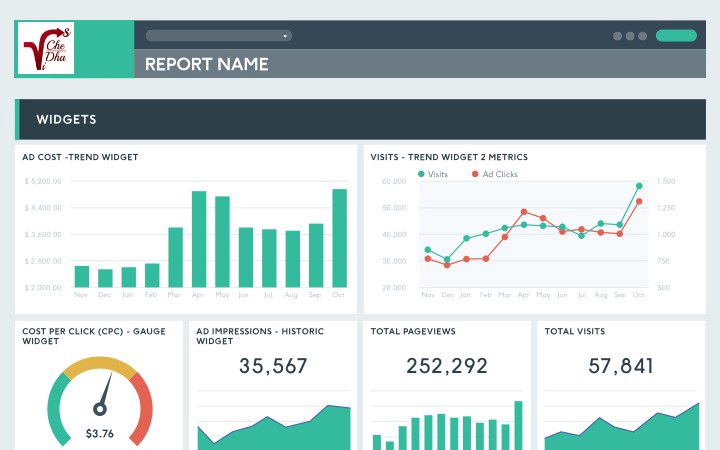

| Automated Dashboards | PdM-ML helps businesses optimize maintenance spending by targeting preventive actions only when necessary, reducing the frequency of unnecessary repairs and overhauls. |  |

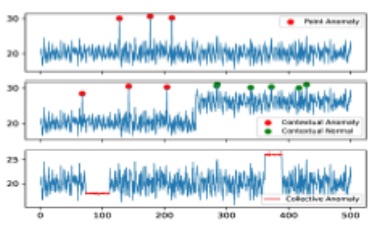

| Anomaly Detection | Vischedha.ai's Anomaly Detection employs advanced algorithms to swiftly identify irregularities, enhancing proactive risk management and fortifying data security. |  |

Vischedha.ai PdM-ML process

The predictive maintenance process with Vischedha.ai begins with the comprehensive collection of relevant data, encompassing sensor readings, historical maintenance records, and performance metrics. Following meticulous preprocessing and feature engineering to enhance data quality and model predictive power, advanced machine learning algorithms are employed for model training. Through rigorous validation and deployment, the model becomes an integral part of real-time operations, generating alerts upon detecting anomalies or predicting potential failures. This initiates a proactive maintenance approach, allowing for root cause analysis and strategic interventions before equipment breakdowns occur. The continuous feedback loop ensures the model's refinement based on real-world performance, contributing to improved asset management, reduced downtime, and enhanced operational efficiency